Precision CNC Systems

Our in-house laboratory is centered around high-precision CNC milling systems dedicated to zirconia and advanced restorative materials. These machines allow us to manufacture prosthetic components with micron-level accuracy, ensuring exact fit, controlled occlusion, and long-term mechanical stability. Supported by digital design stations, 3D scanning, and high-temperature sintering furnaces, our CNC-driven workflow gives us full control over each restoration—from digital planning to final finishing—delivering consistency, predictability, and superior functional outcomes.

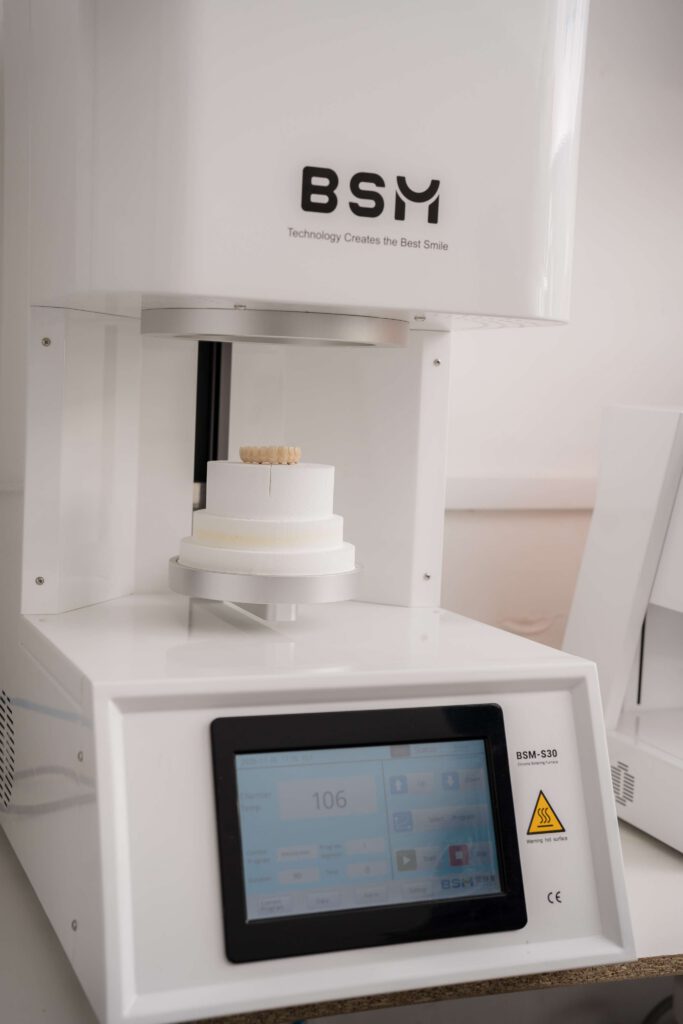

High-Temperature Sintering Furnaces

Our laboratory operates high-temperature sintering furnaces specifically calibrated for zirconia restorations. These systems control heating curves, dwell times, and cooling cycles with precision, allowing zirconia to reach optimal density, strength, and translucency. Proper sintering is critical for long-term durability, marginal accuracy, and aesthetic stability, ensuring that every restoration performs reliably under functional load while maintaining natural optical properties.

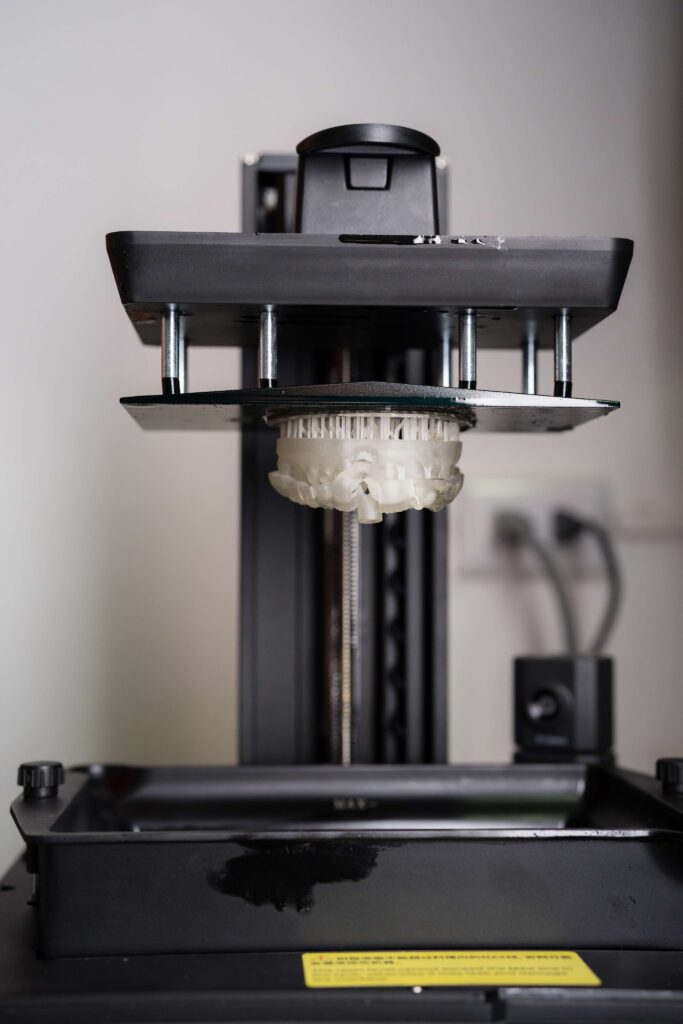

3D Ceramics and modeling

Our in-house 3D printing systems enable precise and rapid prototyping of dental models, including custom implant frameworks and surgical guides. Using advanced digital design stations, we create highly accurate 3D models based on patient-specific anatomy. This process streamlines the workflow from planning to execution, ensuring efficient production and optimized fit for each restoration.